The warehousing and distribution sector has been under the spotlight recently due to the increasing risks associated with its rapid expansion. To address these concerns, the Occupational Safety and Health Administration (OSHA) launched the National Emphasis Program (NEP) on Warehousing and Distribution Center Operations. Here’s a quick debrief on the initiative, the hazards present in warehousing and distribution operations and the product solutions available to help mitigate these risks.

Understanding OSHA’s National Emphasis Program on Warehousing and Distribution Center Operations

The NEP targets nearly two million workers in the warehousing and distribution sector, industries that have seen 156% growth in the course of 10 years––from 668,900 employees in January 2011 to 1,713,900 in December 2021. This rapid expansion has led to an increase in work-related injuries and illnesses, necessitating focused attention on safety measures.

What Industries Are Affected?

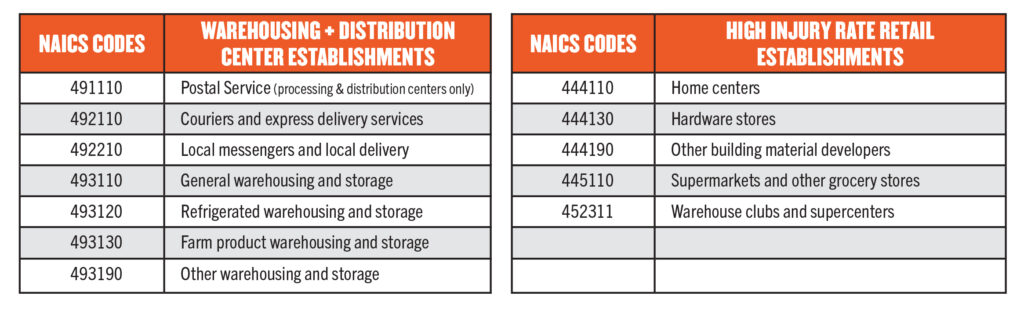

The NEP applies to a range of industries under specific NAICS (North American Industry Classification System) codes, including general warehousing and storage, postal services, courier services and certain high injury rate retail establishments like supermarkets and hardware stores.

Duration and Scope of the NEP

Effective from July 13, 2023, the NEP will be in place for three years. It includes both programmed and unprogrammed inspections, focusing on various workplace hazards such as ergonomic risks, struck-by hazards, heat stress, cold stress in refrigerated warehousing, slips, trips and falls, and material handling.

Click here:

What Type of OSHA Inspections Are Conducted Under the Warehousing NEP?

All inspections under this NEP will focus on workplace hazards common to the above industries including, but not limited to, powered industrial vehicle operations, material handling/storage, walking-working surfaces, means of egress and fire protection. Heat and ergonomic hazards shall be considered during all inspections covered by this NEP and a health inspection shall be conducted if OSHA learns that heat and/or ergonomic hazards are present.

Will Inspections Be Programmed?

Programmed inspections will be guided by a list of establishments falling under the relevant NAICS codes. However, unprogrammed inspections based upon fatalities/catastrophes, complaints or referrals related to establishments in the NAICS codes covered under this NEP shall be expanded to address the workplace hazards targeted.

Examples of Hazards in Warehousing and Distribution Center Settings

- Ergonomic Risks: Tasks involving heavy lifting, bending and repetitive motions pose significant risks.

- Struck-by Hazards: Incidents involving powered industrial trucks are a primary concern.

- Heat Stress: Exposure to high temperatures requires expanded inspection scopes.

- Cold Stress: Working in refrigerated environments necessitates appropriate planning and PPE.

- Slips, Trips and Falls: These common accidents call for proper footwear and good housekeeping practices.

- Material Handling: Hand and forearm protection are crucial when dealing with loads with sharp or rough edges.

Warehouse to Doorstep: Make Safety the Strongest Link in Your Chain

Under pressure? In the clamor of global supply chains, Freddie and Bowie had nothing on today’s warehousing and distribution scene. From temperature management to ergonomics, Ergodyne has the gear that ensures safety and productivity are singing in perfect harmony—from warehouse to doorstep and all points in between.

*This content was provided by Ergodyne